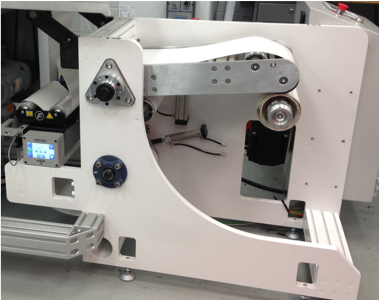

We offer a wide variety of unwind and rewinders with many options: servo-driven, slitters, cantilevered, shaftless, surface, auto lap splicers, turret rewinds, integrated accumulators, and slit stations. We have standard and custom solutions for most winding applications, including nonwoven fabrics, paper, film, foils, foam, and rubber.

Features:

- Digital Dancer and/or load cells for accurate tension control on paper, film, and foil.

- Dancer tension adjustment stored on the touch screen.

- A rewind pressure roller will guide the web to the roll and apply pressure to remove trapped air and build a proper rewound roll. The arm pressure is touch screen controlled and automatically adjusted based on the taper tension settings.

- Taper tension pressure and rate are set in the touch screen and automatically adjusts the pressure roller and the tension to build the highest quality roll for a given substrate.

- Roll diameters are displayed.

- Automatic roll stops on diameter or foot count are standard.

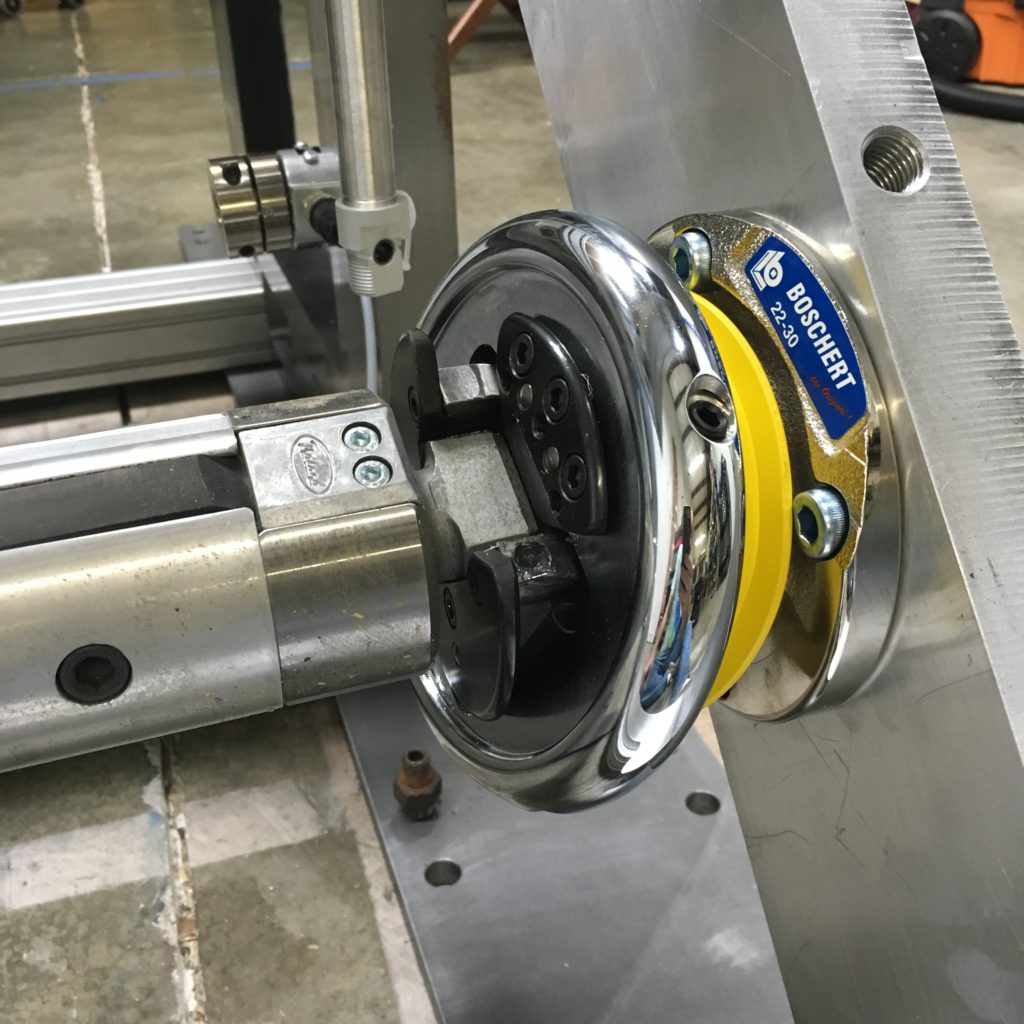

- Boschert Safety chucks are standard in many of our winders.

- Servo, spindle, vector motors for both unwind and rewind application.

We can design a winder to fit almost any application.

General Line Components

The line includes a main control console to house the controller, servo drives and general I/O components. A gear side wire tray will run from the unwind to the rewind above floor height.

Touch Screen Options:

- Unwind tension settings

- Rewind tension settings

- Line speed control

- Print station controls

- Maintenance screen

The servo controller is oversized sized to coordinate multiple winders, 6 printing stations, multiple screens and still have the capacity to grow. Remote maintenance is possible by adding the machine to anInternet-enabled network.

Weldment Winders

The base winders are simple stripped-down winder sets with optional roll lifts, load cell or dancer tension control. Servo rewind can lead with a speed controller or follow with a dancer or load cell. Taper tension option is available. These low-cost winders are designed to run 1000 fpm. Web widths from 10” to 50” and roll diameters from 30″ to 50″.

Unwind & Rewinders